Best asphalt quality thanks to Fliegl push-off technology

For the environmentally friendly production of asphalt, the top priority is to minimize CO2 emissions as much as possible, but without losing quality. The push-off technology contributes a large part to this. The main difference between a thermally insulated tipping body and a push-off vehicle lies in the way the mix is transferred to the paver.

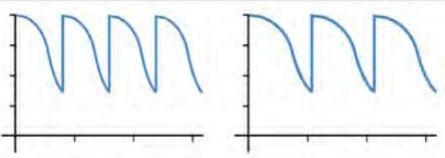

There are slight temperature differences in the loaded building material during transport. A cold layer is created on the surface, which is placed in the paver first during the tipping process, which results in large temperature differences in the asphalt.

If you look at the push-off technology however, the material is pushed into the paver bit by bit. This means that the material has almost the same temperature composition over the entire duration of the unloading process and is therefore equally tempered. In addition, the “bit by bit-dosing” ensures a continuous homogeneity of the mix.

In addition, it is possible to reduce the temperature in the asphalt building process, provided the asphalt is spread using push-off technology - of course without the asphalt quality suffering as a result. Unlike with the tipper, the differently tempered asphalt layers do not slide into the paver separately, but homogeneously and at a uniformly high temperature during the entire unloading process. Temperature fluctuations behind the paving screed are effectively minimized, which means that the asphalt is easy to compact and can be installed evenly. As a result, a much better paving quality and thus a longer durability of the asphalt surfaces is achieved.

Initial road damage can already be avoided when the road is built.

Vehicles with push-off technology, such as Fliegl’s “Asphaltprofi Thermo” are therefore not only environmentally friendly, they are also economically viable. This is also reflected in the maintenance. Due to the higher paving quality, a longer durability of the asphalt layers is guaranteed. This significantly reduces the number of renovation cycles. With the use of thermally insulated push-off trailers, your wallet and the environment are protected at the same time. The continuous push-off process avoids “stop and go” and allows for significantly more running meters.

The push-off technology is also an intelligent solution for difficult installation situations. Trees, overhead lines, bridges and tunnels are no problem. The unloading process is also possible with ceiling heights where tippers reach their limits. Pushing off instead of tipping (over) also generally means more safety and better drivability.